YOUR KEY TO A SMALLER, LIGHTER AND CLEANER LITHIUM-ION BATTERY

Unique silicon-based nano materials making tomorrow´s lithium-ion batteries smaller, cleaner and lighter

Why Choose Us

Cenate’s new proprietary materials offer a series of benefits for your new high energy density anode

- Unique proprietary materials for next generation high density anodes

- Sustainable and safe to use materials made with non-toxic and abundant silicon

- Custom fit for both graphite and non-graphite anodes

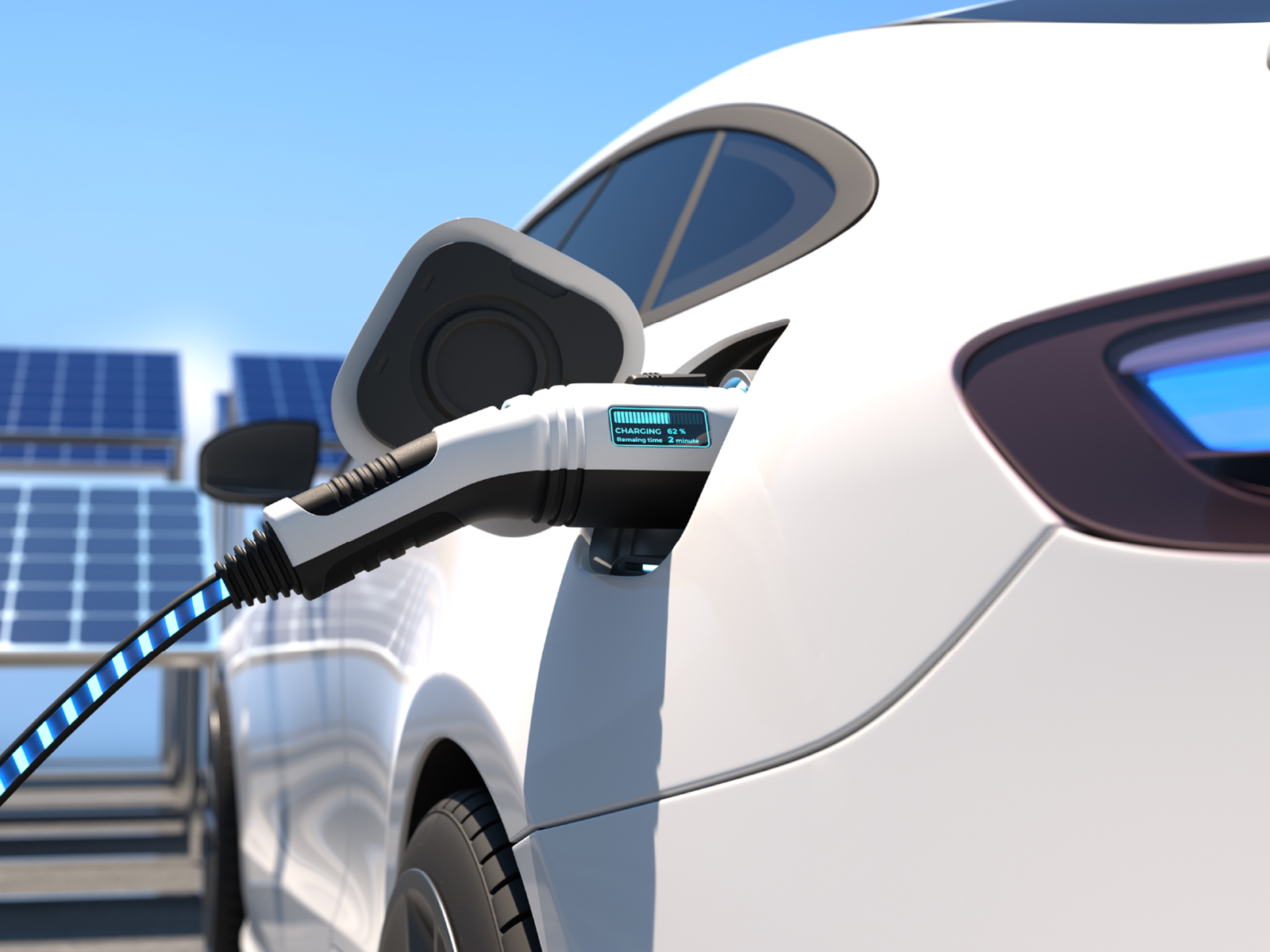

HIGHER ENERGY DENSITY

1 kg Cenate nano-structured silicon replaces 4-6 kg graphite. Cenate’s new & unique product can increase battery energy density by up to 30%.

LOWER CARBON FOOTPRINT

>93% lowered direct CO2 emissions from production (compared to conventional anode materials) and indirect effects from the increased use of EVs. Likely potential for recycling of our material.

INCREASED PRODUCTION CAPACITY WITH LIMITED INVESTMENTS

The overall capacity of batteries produced in a battery factory increases when Cenate’s drop-in replacement materials are used, leading to a higher total number of GWh produced/yr without requiring significant capital investments.

LOWER BATTERY PRODUCTION COST

The battery production costs decrease on a per kWh basis due to higher output from each battery plant and Cenate’s efficient production process.

Collaborative Partnerships

Collaborating with world’s leading battery producers and is currently expanding rapidly.

Silicon anodes are advanced products. Our new anode materials represent a new and critical platform material for this market and can be tailored to your needs.

We collaborate closely with some of the world’s best cell manufacturers for the use of our material in EV batteries. As these type of batteries have very long qualification time and we already are in good collaboration with a significant fraction of the market, we are currently seeking one or two more partnerships with strong cell makers focusing on the portable or aviation electronics market.

About Us

Delivering the key to your silicon anode

Cenate is a Norwegian company developing and producing silicon-containing anode materials to be directly used in today´s lithium-ion batteries.

The company is collaborating with some of the world’s leading battery producers and builds on Norway’s long silicon industrial competence as well as the Dynatec network with its 200 employees.